Sustainable Nanomanufacturing

Technological advancement constantly demands new and unique materials to suit a wide variety of needs. Many material properties such as hydrophilicity/phobicity, biocompatibility, and photonics can be drastically changed through surface modification. Our research aims to combine deposition and irradiation techniques to tailor the surface morphology and chemistry of materials to meet these needs on an industrial scale.

Highlight: Unraveling the mechanisms behind the self-organization of surface morphologies in new material systems for industrial irradiation processing advancement

Much of modern surface modification research has focused on the effects of individual modification techniques on conventional materials. For example, ion beam sputtering of silicon is extremely relevant to the semiconductor industry as photolithography approaches the limits of how small of features it can produce. Our approach is to expand research in areas such as this by utilizing multiple techniques simultaneously, including deposition through evaporation, magnetron sputtering, and molecular beam epitaxy with modification through ion beam sputtering with both focused and broad beam sources.

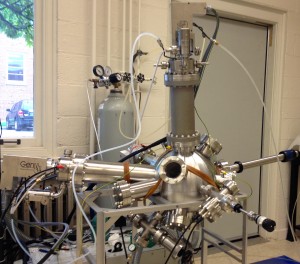

Our focus on Directed Irradiation Synthesis (DIS) is a fundamentally different way of designing materials that will make the next step forward in introducing irradiation as an industrial surface patterning tool. A major challenge that has hindered the widespread rollout of bottom-up fabrication techniques is the minimal control over the final product that stems from insufficient understanding of how surface morphologies develop. The approach of DIS is to establish an understanding of the interplay of multiple processes driving surface feature formation so that these can be controlled and manipulated to synthesize new materials with tailored properties. This is feasible with the IGNIS and MPRIDE facilities, which allow complex material modification with simultaneous in-situ characterization in unconventional areas, specifically dissimilar materials and the high-pressure regime.

Dual Ion Beam Experiment

Above: Chamber, Below, Dual Head Current Plate

Selected Publications

– Jean Paul Allain, Teodoro Tigno, Rocco Armonda, “Nanotechnology in support of a novel neuroendovascular strategy”, in: Nanoneurosurgery, Ed. Babek Kateb and John Heiss, Taylor & Francis, 2013.

– Osman El-Atwani, A. Suslova, A. DeMasi, S. Gonderman, J. Fowler, M. El-Atwani, K. Ludwig, J.P. Allain, “Nanopatterning of metal-coated silicon surfaces via ion beam irradiation: real time x-ray studies reveal the effect of silicide bonding”, J. Appl Phys. 113 (2013) 124305.

– Osman El-Atwani, Sami Ortoleva, Alex Cimaroli and Jean Paul Allain, “Formation of silicon nanodots via ion beam sputtering of ultra-thin gold thin film coatings on Si” Nanoscale Research Letters, 6 (2011) 403.

– J.P. Allain, et al., “IMPACT: a facility to study the interaction of low-energy intense charged particle beams with dynamic heterogeneous surfaces” Review of Scientific Instruments, 78 (2007) 113105

People

Brandon Holybee

Collaborators

Applied Research Institute at UIUC

National Center for Supercomputing Applications.